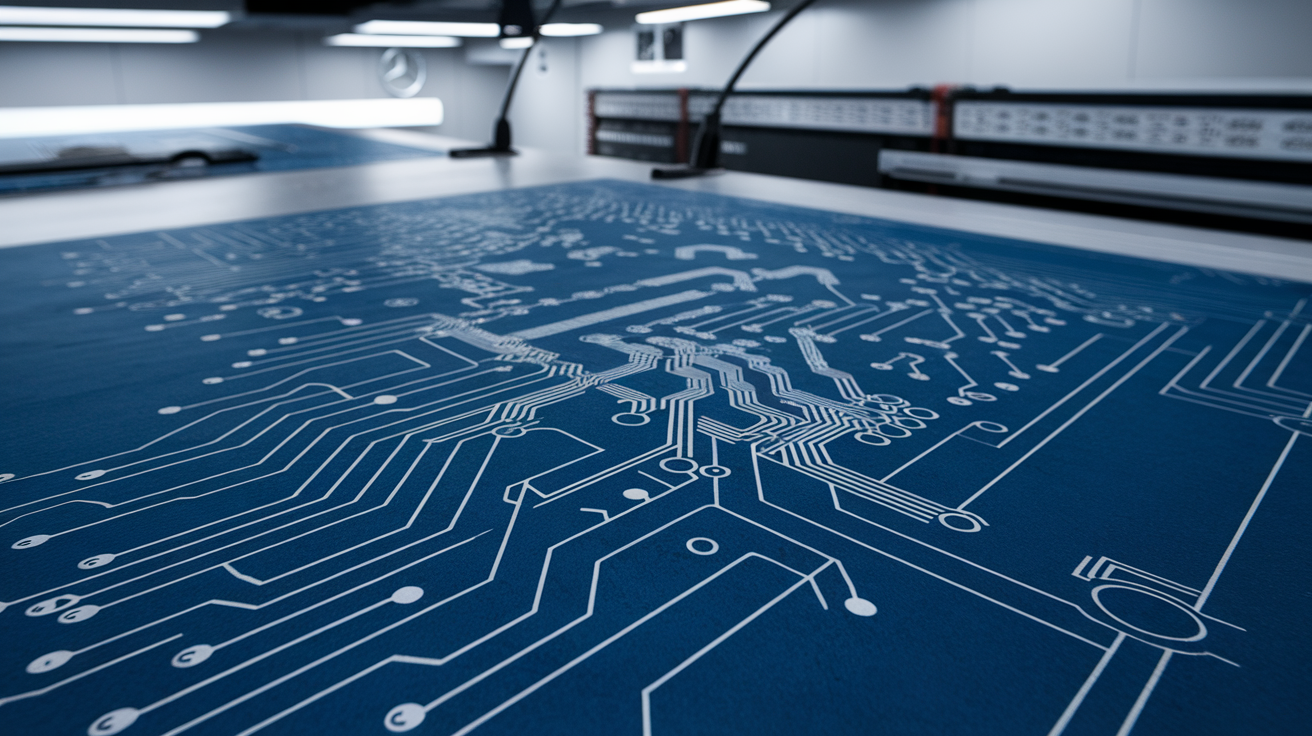

One wrong wire, and you’re chasing faults for hours. Mercedes systems are complex, miss a junction, and you’re pulling panels for nothing. Mercedes Wiring Diagrams are not optional. They’re the first tool a serious technician reaches for. In Dubai’s fast-paced luxury repair scene, they separate guesswork from precision. This guide breaks down how wiring diagrams work, where shortcuts hide, and why they’re essential for electrical troubleshooting in real-world Mercedes repair workflows. Let’s decode what most techs overlook.

Types of Mercedes Wiring Diagrams Used in Repairs | What You’re Looking At

Not all Mercedes Wiring Diagrams are created equal. Some are clean and direct. Others? A maze of modules, junctions, and overlapping systems. Knowing which type you’re dealing with saves hours, and sometimes, the job. Here’s what you’ll find inside a typical service schematic:

Power Distribution Diagrams

Show how voltage moves across systems. Crucial when diagnosing battery drain or blown fuses.

Subtypes include:

- Main power feed maps

- Fuse box layouts

- Relay control paths

Used when diagnosing no-start conditions, blown fuses, or intermittent power loss.

Grounding Maps

Ground faults mimic module failures. These diagrams reveal shared grounding points across systems.

Subtypes include:

- Chassis ground overlays

- Module-specific grounding paths

Essential when multiple systems fail together, often traced to a single bad ground.

Control Module Schematics

Modern Mercedes vehicles run on dozens of modules. These diagrams show how each one connects, communicates, and powers up.

Subtypes include:

Subtypes include:

- ECU pinout maps

- SAM (Signal Acquisition Module) layouts

- TCM and BCM schematics

Used for pinpointing module failures, voltage drops, or signal loss.

CAN Bus Layouts

This is the nervous system. CAN diagrams show how modules talk to each other.

Subtypes include:

- High-speed CAN maps

- Low-speed CAN overlays

- Gateway routing diagrams

Vital when chasing communication faults, especially in post-2015 models.

Mercedes Wiring Diagrams are not just visual aids. They’re diagnostic weapons, if you know how to use them. Each diagram type has its use case. In Dubai’s high-end workshops, techs rely on them to isolate faults fast, whether it’s a misfiring sensor or a dead infotainment screen. Mercedes Wiring Diagrams are not just maps. They’re logic blueprints. Use them like one.

How Mercedes Wiring Diagrams Are Structured | What You’re Looking At

You open a Mercedes Wiring Diagram, and it looks like someone spilled spaghetti across a blueprint. But there’s a method behind the madness. Once you know how to read it, you’ll see logic, not chaos.

Symbols and Legends

Every diagram starts with a legend. It’s not decorative, it’s survival.

- Switches are shown as open or closed gates.

- Relays look like coils or boxes with arrows.

- Sensors often have waveforms or thermistor icons.

- Grounds are marked with downward triangles or horizontal lines.

Tip: A triangle pointing away from a component usually means signal output. Toward it? Input.

Connector Views and Pin Configuration

Mercedes uses detailed connector maps. You’ll see:

- Connector ID (like X30/7)

- PINs and wire colors

- Signal type (voltage, ground, CAN)

Pinouts are critical. One wrong probe, and you fry a module.

Color Coding and Line Types

Wires are color-coded, but not always intuitively.

- Red often means power, but not always.

- Brown is usually ground.

- Blue, green, and yellow carry signals.

Line styles matter too:

- Solid lines = direct connection

- Dashed = optional or conditional

- Dotted = shielded or twisted pair (common in CAN)

Mercedes Wiring Diagrams are dense, but they’re not random. Once you learn the structure, you stop guessing and start diagnosing.

Common Electrical Systems Mapped in Mercedes Wiring Diagrams | Where Faults Hide

Every technician knows this moment: you’ve got a fault code, but no obvious failure. That’s when Mercedes Wiring Diagrams become more than a reference. They become your roadmap. Here’s what they cover, and why each system matters:

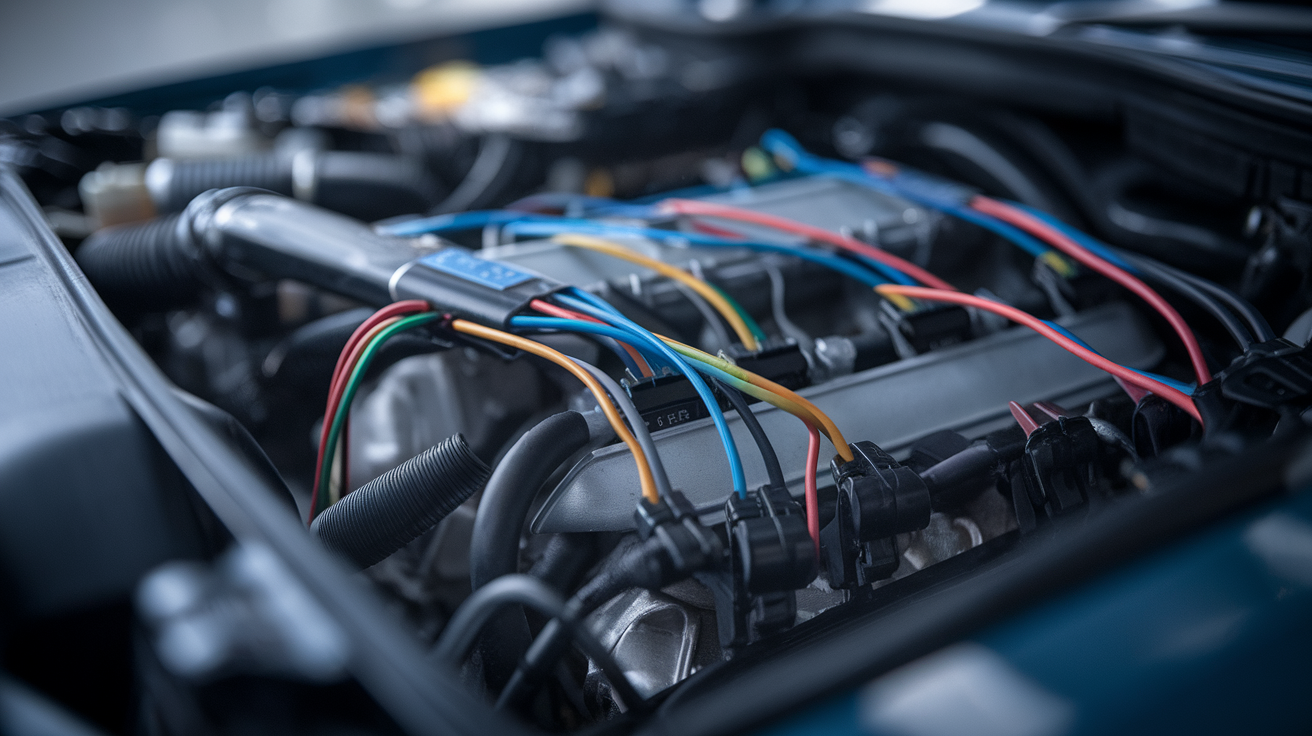

Engine Control Systems

These diagrams show how sensors, actuators, and control units interact.

- Fuel injection paths

- Ignition coil triggers

- Crankshaft and camshaft sensor feeds

Used to isolate misfires, poor fuel economy, or no-start conditions.

Transmission Control

Modern Mercedes gearboxes rely on electronic control.

- TCM (Transmission Control Module) wiring

- Shift solenoid maps

- Speed sensor circuits

Vital when diagnosing harsh shifting, limp mode, or delayed engagement.

HVAC Wiring

Air conditioning in Dubai is not optional.

- Compressor clutch circuits

- Blower motor paths

- The temperature sensor feeds

Used to fix weak airflow, erratic cooling, or dead climate control panels.

Lighting and Indicators

From adaptive headlights to ambient interior lighting.

- Headlight leveling motors

- Turn signal relays

- Brake light switch paths

Used when lights flicker, fail, or trigger warning messages.

Infotainment and Navigation

These systems are CAN-heavy and prone to communication faults.

- Head unit power feeds

- Fiber optic loops

- GPS antenna paths

Used to resolve black screens, audio dropouts, or frozen interfaces.

Fact: A single broken ground in the infotainment loop can disable the rear camera, audio, and navigation, all at once.

Mercedes Wiring Diagrams help you trace the fault, not guess it. That’s the difference between a quick fix and a comeback job.

Hidden Shortcuts in Mercedes Wiring Diagrams | What Most Techs Miss

Have you ever stare at a Mercedes Wiring Diagram and feel like it’s hiding something? It probably is. These diagrams aren’t just maps, they’re layered systems. And if you know where to look, you’ll find shortcuts that save hours.

Alternate Diagnostic Paths

Let’s say you’re chasing a fault in the rear SAM module. The obvious path runs through the fuse box, relay, and control unit. But there’s often a bypass route, a shared power feed that connects through a junction block under the rear seat. Skip the fuse box. Go straight to the junction. That’s 30 minutes saved.

Real case: A 2018 GLC with intermittent tail light failure. The fault was traced not through the SAM, but via a shared power feed tucked behind the left trim panel.

Shared Grounds and Power Feeds

Mercedes loves shared grounding. One ground point can serve five systems.

- Miss it, and you’ll think five modules failed.

- Find it, and you fix all five with one bolt.

Mercedes Wiring Diagrams often bury these shared grounds in the lower layers. You have to zoom in, trace backward, and look for the triangle that’s not labeled. That’s your shortcut.

Hidden Junctions

Some junctions aren’t listed in the main schematic. They show up only in sub-diagrams, especially in CAN layouts.

- These junctions reroute signals when modules go into fallback mode.

- If you know where they are, you can test signal integrity without pulling half the dashboard.

Tip: Always check the CAN overlay for gateway reroutes. A failed gateway in a 2020 E-Class rerouted signals through the infotainment module, completely undocumented in the main schematic.

Why It Matters?

In Dubai’s high-volume workshops, time is not just money; it’s reputation. Knowing how to read between the lines of Mercedes Wiring Diagrams means faster fault tracing, fewer comebacks, and cleaner repairs.

Model-Specific Wiring Diagram Variations | Why VIN Precision Matters

You think you’ve got the right Mercedes Wiring Diagram—until the wire colors don’t match, and the connector ID is missing. That’s not a misprint. It’s a model mismatch.

Platform Differences

Mercedes doesn’t just change body shapes across platforms. It rewires them.

- E-Class (W213)

Uses modular architecture. Diagrams are clean, with separate layers for drivetrain, body, and comfort systems.

CAN networks are split, one for the powertrain, one for interior electronics. - S-Class (W222/W223)

A wiring jungle. Expect:- Redundant power feeds for safety systems

- Fiber optic loops for infotainment

- Multi-gateway CAN routing

Diagrams often exceed 30 pages per system. You’ll need sub-diagrams just to trace a single fault.

- C-Class (W205)

Compact but dense.

- Shared grounds across the lighting and body modules

- Integrated HVAC and infotainment control units

- Fewer junction blocks, tighter routing

One missed splice, and you’re chasing phantom faults.

A case | A 2020 C-Class with a dead blower motor. The fault was traced to a shared ground buried in the rear fuse box, not listed in the main HVAC diagram.

Trim-Level Complexity

An AMG variant? Expect extra wiring for:

- Active suspension

- Exhaust valve control

- Performance sensors

Base models? Fewer modules, but more shared circuits—harder to isolate.

VIN-Specific Diagrams

Mercedes updates wiring mid-year. Even two cars with the same model name can have different layouts.

- Always use diagrams tied to the VIN.

- Avoid generic PDFs, as they miss hidden junctions and updated module paths.

Mercedes Wiring Diagrams are not universal. They’re tailored blueprints. Treat them like surgical maps; one wrong cut, and you’re chasing ghosts.

Tools Required to Interpret Mercedes Wiring Diagrams | What You Need on the Bench

Reading Mercedes Wiring Diagrams is not just about staring at lines and symbols. You need tools, real ones. Without them, you’re guessing. And in a Mercedes, guessing gets expensive.

Digital Multimeter (DMM)

The digital multimeter is your first weapon. It’s not optional, it’s essential. You’ll use it to measure voltage, resistance, and continuity across circuits. Diagrams may show a clean power path, but unless you test voltage under load, you’re only seeing theory. A wire might read 12 volts static, then drop under current. That’s the kind of fault you won’t catch without proper testing. Always confirm what the diagram shows—don’t assume it’s accurate just because it looks clean.

Circuit Tester

The circuit tester is fast, simple, and often underrated. It’s perfect for checking fuse circuits and relay outputs when you need a quick yes or no on power delivery. But it’s not precise enough for CAN bus lines or signal wires. Use it for fast checks, not deep diagnostics. It’s a tool for speed, not depth.

Diagnostic Scanner

This is where things get serious. A diagnostic scanner does more than read fault codes; it maps module communication, shows live data, and confirms whether the wiring path shown in the diagram is functioning. Without it, you’re relying on assumptions. In one real case, a 2021 GLE had a dead rear camera. No fault codes appeared. The scanner showed no errors, but the Mercedes Wiring Diagram revealed a broken signal wire between the gateway and the camera module. That’s the kind of issue scanners and diagrams must solve together.

Wiring Diagram Software or Viewer

The diagram viewer itself matters more than most techs realize. Static PDFs are risky. They often miss sub-diagrams, VIN-specific changes, or updated module paths. You need a platform that lets you zoom, layer, and search. OEM portals or licensed software are preferred. That’s how you turn Mercedes Wiring Diagrams into real diagnostic tools, not just reference sheets. Without the right viewer, you’re reading a map with no compass.

Mercedes Wiring Diagrams are only half the battle. The right tools make them usable. Without them, you’re reading a map with no compass.

Mercedes Wiring Diagrams in Fault Code Diagnostics

Mercedes Wiring Diagrams aren’t just for tracing wires; they’re diagnostic weapons. When a vehicle throws fault codes, the diagram becomes your roadmap. It shows how modules connect, where signals flow, and which components share power or ground paths. Without it, you’re chasing ghosts.

How Diagrams Assist in Decoding Fault Codes?

Mercedes Wiring Diagrams are more than visual aids; they’re diagnostic frameworks. When a vehicle throws fault codes, the diagram helps you decode the logic behind the error. It shows how modules are powered, grounded, and interconnected. Without this map, you’re relying solely on scanner data, which often lacks context. Diagrams reveal whether a fault is due to a broken wire, a shared ground, or a missing signal, not just what the ECU reports.

Mapping DTCs to Wiring Paths

Every DTC tracing session should begin with the diagram. It lets you follow the fault from the ECU to the component, through connectors, fuses, and shared circuits. For example, a Mercedes error code for a sensor might stem from a voltage drop caused by a failing relay upstream. Diagrams expose these indirect paths, something no scanner can visualize.

Case Examples of Fault Resolution Using Diagrams

Take a 2019 E-Class with intermittent CAN faults. The scanner flagged the gateway module, but the Mercedes Wiring Diagram revealed a corroded splice point affecting multiple ECUs. Replacing the gateway wouldn’t solve it; repairing the splice did. This is why diagrams are central to any diagnostic workflow. They turn fault codes into solvable problems.

Accessing and Managing Mercedes Wiring Diagrams

Mercedes Wiring Diagrams are only as powerful as the platform you use to view them. Whether you’re diagnosing a complex CAN fault or tracing a simple ground issue, the accuracy and accessibility of your diagrams determine how fast and how correctly you solve the problem. But not all diagrams are created equal. From OEM service portals to outdated PDFs, the source and version of your wiring documentation can make or break your diagnostic workflow.

Sources for Authentic Diagrams (OEM, Licensed Platforms)

To work effectively with Mercedes Wiring Diagrams, you need access to the real thing—not generic PDFs floating around forums. The most reliable sources are OEM service portals and licensed platforms that offer VIN-specific schematics. These tools provide layered views, module maps, and search functions that static documents simply can’t match. If you’re serious about diagnostics, invest in platforms that mirror Mercedes’ internal documentation.

Importance of Version Control and Updates

Wiring evolves. A 2020 model may have mid-year changes in ECU mapping, connector layouts, or fuse assignments. That’s why version control matters. Authentic platforms update diagrams based on production runs, service bulletins, and retrofit changes. Using outdated schematics leads to misdiagnosis, wasted labor, and damaged components.

Avoiding Outdated or Generic Schematics

Avoid PDF schematics unless they’re verified and current. Many are stripped of sub-diagrams, lack module overlays, and miss critical updates. In Mercedes diagnostics, precision matters, and that starts with the right Mercedes repair documentation.

Strategic Use of Mercedes Wiring Diagrams in Professional Repairs

Mercedes Wiring Diagrams aren’t optional; they’re strategic tools that elevate your entire repair strategy. From pinpointing electrical fault resolution to enhancing diagnostic accuracy, they turn guesswork into precision. Whether you’re chasing intermittent CAN issues or verifying power delivery, diagrams provide the clarity needed to avoid costly mistakes.

For any serious technician, integrating Mercedes Wiring Diagrams into every diagnostic workflow isn’t just smart, it’s essential. They streamline Mercedes service optimization, reduce downtime, and ensure repairs are done right the first time. Use them professionally, consistently, and with the right tools, and your diagnostics will never be blind again.